Building template grinder

Mobile/WhatsApp: 008613592505674

http://www.vidacrusher.com

►1. Site template introduction:

Site template is actually the site wood template, it is used to pour concrete when the frame, that is to maintain the shape of concrete, it is solidified after you do the shape of the box inside the box, the popular name is the shell Board, wood template, steel template knowledge can be found in the construction manual, or in the general school building construction textbooks to see. Modern construction, often used shell board, these wooden shell board, because the construction of the loss, was a large number of abandoned, resulting in a great waste.

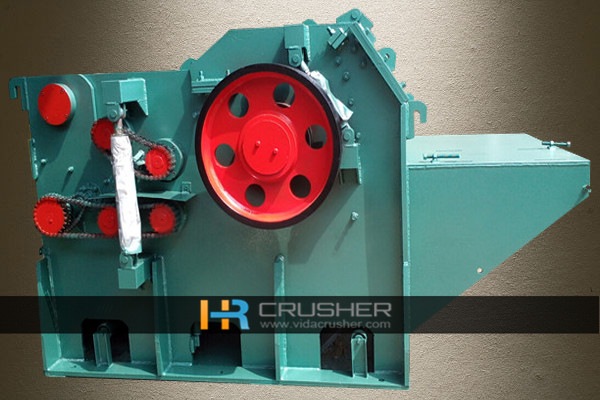

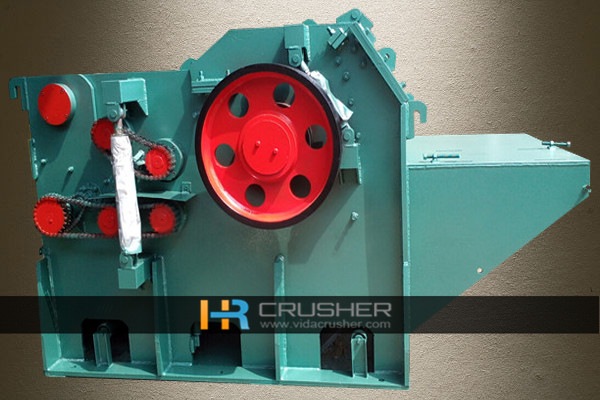

►2. Template Shredder Overview:

The material used to mold the crusher is mainly waste wood, such as waste building templates, wooden pallets, containers, crates and the like. These wood, can not avoid the nail, with ordinary wood chip processing will damage the machine blade, and I plant the production of the template crusher is a wood crushing machinery and equipment, not afraid of the site on the bamboo sheet or cargo tray nails. The hydraulic opening device is used for opening and closing of the cabinet, which can effectively reduce the maintenance labor intensity, improve the maintenance efficiency and shorten the maintenance working time. Box-type crusher monitoring system can monitor the operation of the crusher at any time to monitor the signal can be interlocked with the main control system to ensure the safety of the machine, reliable operation. The hydraulic opening device of the template grinder is used to open and close the cabinet, which can effectively reduce the maintenance labor intensity, improve the maintenance efficiency and shorten the maintenance work time. The electrical monitoring system can monitor the running status of the crusher at any time. The monitoring signal can be interlocked with the main control system to ensure the safe and reliable operation of the machine. It is the ideal choice for crushing bamboo panels, scrap templates on the site, wooden pallets and other materials.

►3. Structure:

Building template grinder mainly by the rack, shell, motor base, shaft, hammer, screw conveyor, induced draft fan and other components, and not afraid of the site on the bamboo sheet or cargo tray nails, is a professional crushed bamboo sheet, Waste templates, wooden pallets and other materials ideal equipment.

►4. Working principle

The construction template shredder consists of the main part of the feed roller and the conveyor. Feeding: Place the wood to be broken. Feed roller: control the feed speed and keep the sheet from slipping and not feeding ; Screw crushing roller: in the roll along the circumference of the uniform welding of the cutter to ensure that the crushing roller in the circumferential direction of the same force; feed pressure roller with UCK series bearing plus spring compression mechanism, can be adapted to the different thickness of the plate broken ; Feed pressure roller and crushing roller with different power system, easy to control.

►5. Template grinder use and maintenance instructions:

►5. Template grinder use and maintenance instructions:

1) before the start of the test to strictly check the installation of the various parts of the machine to meet the requirements, whether the loose screw bolts, hand gently pull the belt test, whether the shell case and so on. At the same time check the direction of rotation, is strictly prohibited smashing flammable, explosive items, so as to avoid accidents.

2) the production should be kept evenly to ensure the quality of crushing and normal production, while the motor overload is strictly prohibited to ensure the normal operation of the machine.

3) In addition to regular attention to check the various parts of the fastening, but also should pay attention to check the wearing parts of the wear and tear, such as serious wear and tear should be replaced in time to avoid damage to the main components. And take the necessary fire protection measures.

4) Due to the high speed, in addition to the installation of a firm and solid, while maintaining good lubrication to maintain the normal operation of the machine. Under normal circumstances the bearing temperature does not exceed 70 degrees normal. Host bearing a week to add butter, molybdenum disulfide, high-speed butter better.

►

6.Before and after crushing:

Before

After

After

HR1200 Large recycling bases Mu

HR1200 Large recycling bases Mu Plastic Crusher Plastic Recycli

Plastic Crusher Plastic Recycli Plastic Crusher

Plastic Crusher Scrap Aluminum Crusher

Scrap Aluminum Crusher