Plastic Shredder Product Introduction

Model Series: 600, 800, 1200

Core Function:

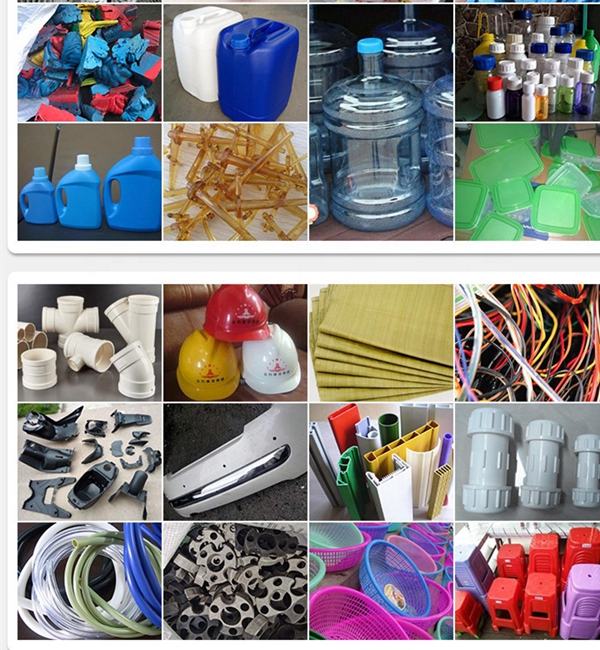

Plastic shredders use high-speed rotating blades to break waste plastics into granular or flake materials, facilitating subsequent cleaning, melting, and recycling. The equipment processes daily consumer plastics (e.g., bottles, films, toys) and industrial waste (e.g., pipes, sheets), achieving "reduction, resource recovery, and pollution control" goals.

Why Choose a Plastic Shredder?

-

Environmental Needs

-

Over 300 million tons of plastic waste are generated globally each year. Traditional landfill or incineration methods cause soil pollution, greenhouse gas emissions, and microplastic dispersion.

-

Shredded plastic particles can be reused to manufacture daily products, building materials, etc., reducing virgin plastic production (each ton of recycled plastic cuts 1.5 tons of carbon emissions).

-

Policy Drivers

-

China’s 14th Five-Year Plan for Circular Economy mandates a basic plastic pollution control system by 2025, enforcing waste classification and recycling.

-

The EU’s Packaging and Packaging Waste Regulation requires 30%-35% recycled content in plastic packaging by 2030, driving demand for recycled granules.

-

Economic Benefits

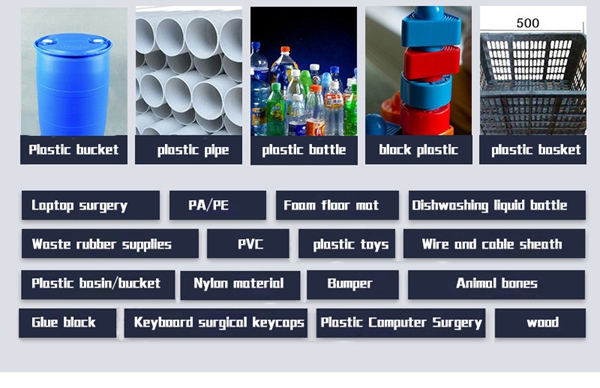

Processable Plastic Types

|

Plastic Type |

Common Applications |

Shredding Compatibility |

|

PET |

Beverage bottles, food packaging |

High (easily crushed into uniform particles) |

|

HDPE |

Cosmetic bottles, toys, barrels |

High (requires adjustable blade speed) |

|

PVC |

Pipes, construction materials |

Medium (anti-stick blade design needed) |

|

PP |

Tableware, automotive parts |

High (heat-resistant shredding) |

|

LDPE |

Plastic bags, agricultural film |

Medium (anti-tangling structure required) |

Note: This series supports mixed plastics (e.g., landfill waste) with optimized blades to reduce sorting costs.

Global Plastic Recycling Policies & Trends

-

China

-

Implements "Plastic Ban Policy," prohibiting ultra-thin plastic bags and enforcing waste classification. Pilot projects in Shanghai/Shenzhen promote professional plastic recycling.

-

2025 Target: Key industries (construction, appliances) must use ≥5% recycled materials.

-

EU

-

By 2030, PET bottles must contain ≥30% recycled content; other packaging ≥35%.

-

Germany’s "Deposit System" achieves >98% plastic bottle recycling.

-

USA

-

Developing Countries

Hazards of Plastic Waste

-

Environmental Damage

-

Ocean pollution: 85% of marine debris is plastic, threatening marine life and entering human food chains.

-

Soil degradation: Landfilled plastics release toxins, harming crop growth.

-

Health Risks

-

Microplastic Invasion: Microplastics detected in human brains/livers (4,800 µg per gram of brain tissue), linked to inflammation and Parkinson’s disease risks.

-

Chemical Toxicity: Phthalates and BPA in plastics disrupt endocrine systems, affecting reproductive health.

-

Economic Loss

Model Selection Guide

Model Selection Guide

|

Model |

Application Scenarios |

Capacity (kg/h) |

Key Advantages |

|

600 |

Medium plastic processing plants |

500-800 |

Wear-resistant blades, auto-feeding |

|

800 |

Large factories, industrial parks |

1000-1500 |

High throughput, energy-saving motor |

|

1200 |

Large recycling bases |

1500-2000 |

Multi-stage shredding, smart sorting |

Technical Support & Compliance

This series complies with China’s Plastic Waste Recycling Guidelines and supports customization for EU/Southeast Asian markets. Free technical training and policy compliance guidance provided.

This framework can be enriched with images, case studies, and policy document links to enhance credibility.