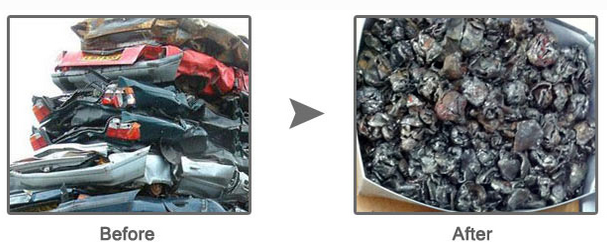

Low noise, no pollution, high crushing efficiency, fine and uniform discharging particles.

►5.The advantages of Metal briquette crusher

Scrap metal crusher crushing chamber can be fully and effectively crushed, high yield, low energy consumption, high efficiency, uniform discharge, adjustable size. And when using the device, the noise is low, smooth operation, no pollution, simple operation, easy maintenance. The machine also applies to more fragile metal materials broken and crushed.

►6. Professional Service

As a professional crusher(shredder) manufacturer in China, we provide the most powerful large metal crusher, cans crusher, scrap crushing production line.

Free consulting service;

Suggestion on operation scale and plant program according to clients’ needs;

Send experienced engineer to help clients on the installation, commissioning and operator training;

For crushing plant, we provide 18 months warranty and lifetime maintenance;

Provide technical advice and give technical diagnostics;

Help users on their system and equipment upgrades;

Supply of accessories;

Regularly visit users, collect feedback and meet customer needs.

Should this large type scrap metal crusher or scrap recycling equipments be of interest to you, please do not hesitate to contact us or complete the form below, and we will response to you as soon as possible.

HR1200 Large recycling bases Mu

HR1200 Large recycling bases Mu Plastic Crusher Plastic Recycli

Plastic Crusher Plastic Recycli Plastic Crusher

Plastic Crusher Scrap Aluminum Crusher

Scrap Aluminum Crusher