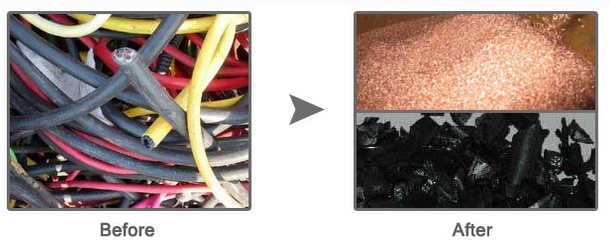

Scrap Wire and Cable Recycling Equipment

Mobile/WhatsApp: 008613592505674

►1.Brief Introduction:

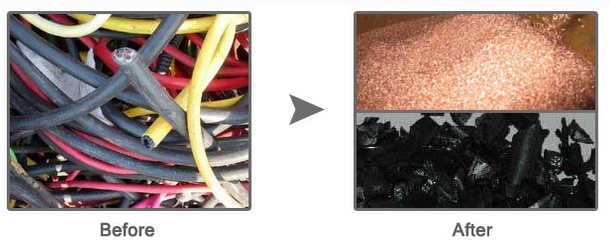

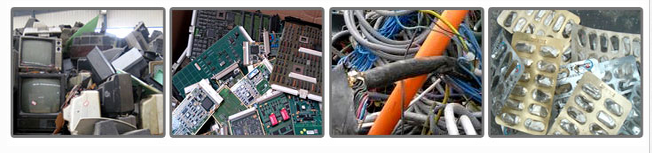

The scrap wire and cable recycling equipment is designed to process car circuit wire, communication cables and miscellaneous material cables that can not processed by stripping machine. The recycling machine adopt dry crushing principle. After the crushing process and electrostatic separation, plastic and copper can be completely separated without dust and secondary pollution.

►2.Working Principle:

Crush the scrap cables, wires to make the plastic and metal separated;

Metal and plastic or other non-metal will be separated by high-voltage electrostatic separator.

Feed the material into the combination crushing plants, and the mixed material is processed by automatic transmission, soundproof, cooling systems, etc. Finally to get the metal and non-metallic material recycled separated.

This equipment also uses a triple dust removal device developed: the cyclone, bag filter and air cleaner, which effectively solve the problem of dust pollution.

►3.Customization Requirements Cable and Wire Recycling Equipment:

Due to the different models of scrap wire/cable, the configurations of crushers, shredders, elevator, conveyor and separator can be also different. We can customize the right production line according to the customers’ needs, even for the 0.1mm wire crushing and recycling.

Customers can bring their own wire/cable samples to our factory for the free crushing test.

we provides customers with long-term technical advice, support, comprehensive after-sales service and suggestions on factory construction.

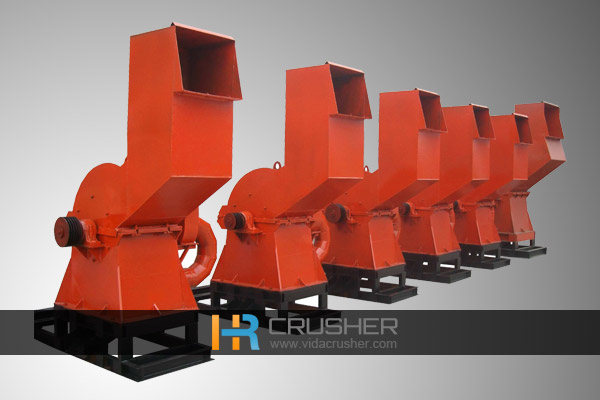

►4.Cable crusher configuration:

►4.Cable crusher configuration:

Shredding blade set, carrying the box, the box bracket, feed system, power system, electrical control system composed of the machine.

►5.Cable crusher Features:

1)ultra-low speed, high torque, 5 to 13 per minute turn;

2)Low noise, low dust;

3)Optional motor or hydraulic motor;

4)For the different nature of the material, the customer free to choose the overall type of shredded blade or assembled removable blade;

5)Optional hydraulic forced feeding device, more efficient and fast to tear the material;

6)Double end of the shaft at both ends of the structure to ensure that the installation position of the blade to prevent axial displacement;

7)Using microcomputer (PLC) automatic control, set start, stop, reverse and overload automatic reverse control function;

8)80 ~ 100 hours before leaving the factory feeding test to ensure the reliability of equipment.

HR1200 Large recycling bases Mu

HR1200 Large recycling bases Mu Plastic Crusher Plastic Recycli

Plastic Crusher Plastic Recycli Plastic Crusher

Plastic Crusher Scrap Aluminum Crusher

Scrap Aluminum Crusher