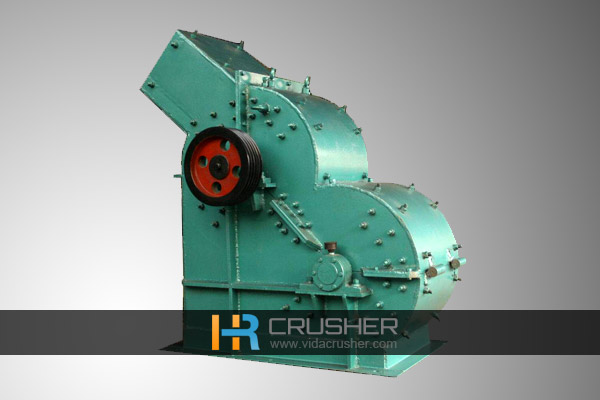

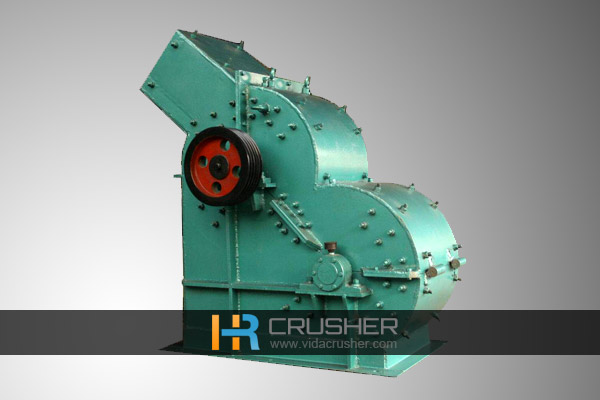

Washing machine crusher

Mobile/WhatsApp: 008613592505674

http://www.vidacrusher.com

►1. Application:

Washing machine crusher is mainly used for grinding waste bucket, thin metal sheet, scrap metal slag, beer cans, metal bottles, Coke cans, beverage cans, paint barrels, tin cans, etc., the use of small and medium enterprises is the best.

►2. Advantages:

The washing machine crusher takes full advantage of the impact, shearing, blow molding and grinding forces, it is a new type of efficient tanker, waste cans can be completely crushed. Washing machine crusher high yield, low energy consumption, high efficiency, grinding and other advantages.

►3.Main features:

1)Low speed, large torque cut

2)Low dust, low noise

3)Low maintenance frequency

4)Reducer is equipped with vibration damping device to protect the transmission parts

5)The tool is made of high-strength alloy heat treatment, suitable for cutting a variety of high-strength materials

6)Install the arc-shaped partition on both sides of the box to ensure smooth discharge and increase production

7)Modular design of the box, equipped with independent side panels and bearing, easy maintenance

8)Advanced sealing system to prevent leakage of material from the box to ensure bearing life

►4. Structure:

Using 25mm - 30mm thick steel plate made of automatic welding, the internal set with high manganese steel liner, the external plus stirrups, so that the whole machine durable. Using the fixed knife and the knife combined with each other, set the knife for the S-shaped fixed at the top of the cutter, the material into the case, the force to play and forced the role of broken. Moving knife for the head, when the material through the knife after the strong tear, with the turntable rotation in the final process of forming less than the sieve particles, the screen filter into the outlet. In the discharge at the same time through the dust collector, thoroughly put the patent leather and impurities sucked away, is broken metal particles clean, bright, reduce pollution. Screen can be customized according to material and user needs.

►5. Washing machine crusher process:

material - transport - the host - dust - transport - aluminum and iron separation

HR1200 Large recycling bases Mu

HR1200 Large recycling bases Mu Plastic Crusher Plastic Recycli

Plastic Crusher Plastic Recycli Plastic Crusher

Plastic Crusher Scrap Aluminum Crusher

Scrap Aluminum Crusher