4) Applicable to other raw materials such as corn straw, wheat straw, cotton rod, straw, rice husk, peanut shell, corn cob, branches, leaves, sawdust and other agricultural products as raw materials or wood factory foot Material) of the compression molding.

►3. working principle

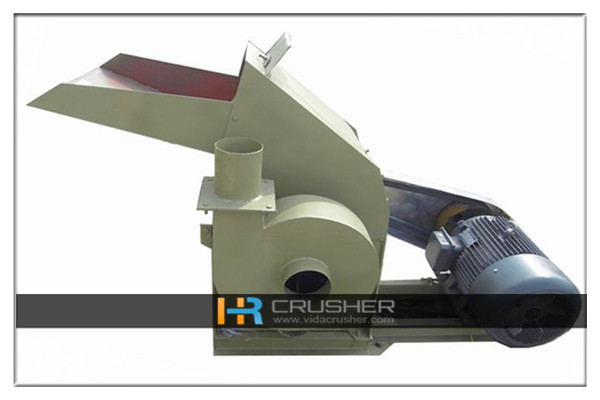

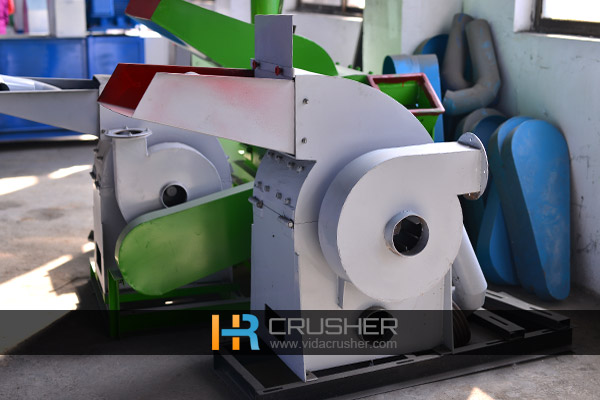

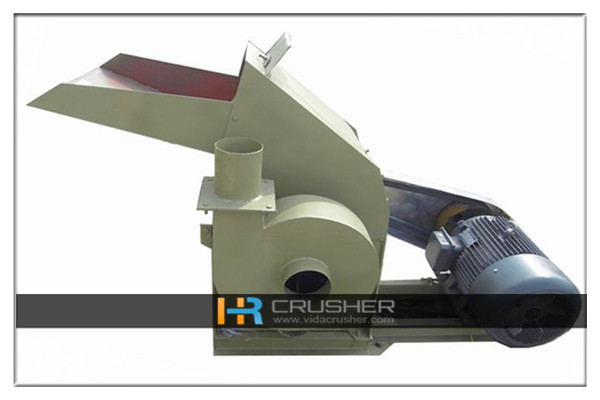

Straw crusher can be equipped with motor, diesel engine or 30-50 horsepower tractor, the host by the feeding mechanism, cutting mechanism, throwing institutions, transmission, travel agencies, protective devices and racks and other components. With reasonable structure, easy to move, automatic feeding, safe and reliable and so on.

The parts are as follows:

1) Feeding institutions: mainly by the feeding station, up and down Cao Kun, set the blade, set the knife bearing seat.

2) cut off the throwing institutions: mainly by the knife, cutter, locking screws and other components.

3) Transmission: mainly by the V-belt, drive shaft, gear, universal joints and other components.

4) walking institutions: mainly composed of caster.

5) protective device: by the protective cover composition.

►4. Use skills

Straw shredder of the top ten safe use of skills

1) Straw crusher should be fixed on the ground, you can use cement to fix. Such as frequent changes in the workplace, grinder and motor to be installed in the angle made of the base.

2) Straw grinder should be carefully installed after installation to install in place to check whether the installation is not strong enough. Whether the motor shaft and the pulverizer shaft are parallel, and check that the belt tightness is appropriate.

3) before the start of the straw shredder, first turn the rotor by hand to check whether the operation is flexible and normal, whether the collision within the chassis, the direction of rotation of the rotor is correct, motor and pulverizer lubrication is good and so on.

4) Straw mill do not often change the pulley, to prevent the speed is too high or too low.

5) straw shredder should be idle after the start of 2 to 3 minutes, no abnormal phenomenon after feeding work.

6) Straw crusher to be uniform, if found to have noise, bearing and body temperature is too high or outward spray and other phenomena, should immediately stop inspection, troubleshooting.

7) Straw crusher work before the staff should carefully check the material to prevent metal, stone and other hard objects into the crushing chamber caused by the accident.

8) When feeding, the staff should stand on the side of the straw shredder to prevent the debris from being bounced out. Smash the long stalk when the hand can not be too tight to prevent the hand was brought into.

9) Straw crusher in the stop before the first stop feeding, standby material removed after the clean, and then cut off the power supply shutdown. After cleaning to carry out cleaning and maintenance.

10) straw shredder 300 hours after operation, to be cleaned bearings, replacement of oil; installed oil, to full bearing clearance of 1/3 as well, up to no more than 1/2. For long periods of time, remove the belt.

►5. Maintenance and maintenance

1) regularly check the power, check the power outlet, plug, power cord with or without oxygen off, broken place.

2) regularly check the bearing lubrication is good, and regular use of lubricating oil maintenance.

3) regularly check all fasteners are fastened, if there is loosening phenomenon should be promptly handled.

4) regularly check the drive belt is installed correctly and in good condition, if found damaged belt should be replaced, when the belt or sheave on the oil, the application of clean wipes in time to wipe.

5) regularly check the protective device is good, if found to have unsafe protective device, should be promptly excluded.

6) regularly check the damaged cavity with or without material or other debris, if sometimes should be cleaned.

7) regularly check the top of the hydraulic head or from the top of the screw is returned, adjust the gasket is installed correctly and pressed.

8) regularly check the fan seal, to prevent the sand on the fan will cause serious wear and tear, so that the wheel body and the wheel rivet head off, and rivet hole fatigue crack.

►6. Maintenance:

1) If the rivet head of the impeller is worn, it can be welded by pressing the impeller body and the hub with the welding, so that the wear of the rivet head back to the original normal state.

2) on the rivet hole prone to fatigue crack situation, the whole can not use the new electrode welding repair crack, but to the impeller axis line as the center of symmetry, the crack at the end of the welding of the remaining welding rod In this place, and then use a new electrode to repair the symmetrical rivet hole cracks, welding the remaining electrode and the symmetrical rivets repair the same as the remaining electrode to ensure that the welding up the same weight. If there is no crack in the symmetrical rivet hole, the electrode should be welded here to offset the new welding weight of the symmetrical rivet hole. According to this method of symmetrical replenishment welding can repair cracks.

3) the impeller for a simple dynamic balance test, the method is also very simple. The impeller support after the hand to make it gently rotation, reach the balance of the place will stop to the lowest point and left and right swing. If you can focus on the opposite impeller on the spot welding, increase the weight to balance, or worn with a corner mill to focus on the impeller of the welding marks, but also to achieve balance, so that the fan can be repaired to work properly. Note that in the process of repairing the fan can not be welded by welding at random, the welding marks left to the impeller, so as not to affect the balance of the fan impeller, fail to repair the purpose, resulting in greater losses.

►7. Safe use requirements

1) the operator should stand on the side of the work, to prevent hard objects from the feed mouth pop.

2) is strictly prohibited into the feed mouth and forced feeding, is strictly prohibited with sticks to help feed, to prevent injury damage machine.

3) found that the work of the straw mill is not normal or abnormal sound, should immediately shut down to cut off the power, until the machine completely stopped and then open the lid inspection, the machine is strictly prohibited to check, identify the reasons, troubleshooting and then work.

4) Operation can not arbitrarily increase the spindle speed, to prevent high-speed suspension when the loss of damage to the machine, resulting in unnecessary losses.

5) Straw crusher work process, the operator must not leave the job, need to leave when the need to stop power.

6) under 18 years of age and the elderly, the mind is not clear who may not boot operation; stay long hair lesbian operation must wear a work cap; the operator shall not drink job.

7) Straw crusher in the process of work, because the speed is very high, we must pay attention to see the operation of the straw mill, if the body closed lax, then the dust will blow into the air, causing the work environment pollution, and sometimes The fan caused by wear and tear, if the serious will make the impeller off, not timely maintenance, but also may make the fan scrapped. Therefore, before the formal work, the straw grinder fan device must go through the dynamic balance experiment.

HR1200 Large recycling bases Mu

HR1200 Large recycling bases Mu Plastic Crusher Plastic Recycli

Plastic Crusher Plastic Recycli Plastic Crusher

Plastic Crusher Scrap Aluminum Crusher

Scrap Aluminum Crusher