Scrap Steel Crushing Line

Email: sales@hwdcrusher.com

Mobile/WhatsApp: 008613592505674

http://www.vidacrusher.com

►1.Introduction of Scrap Steel Crushing Line

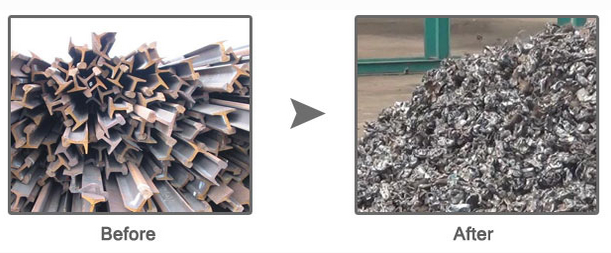

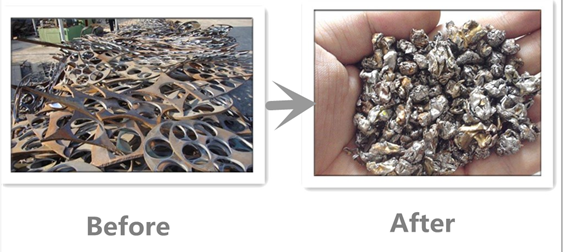

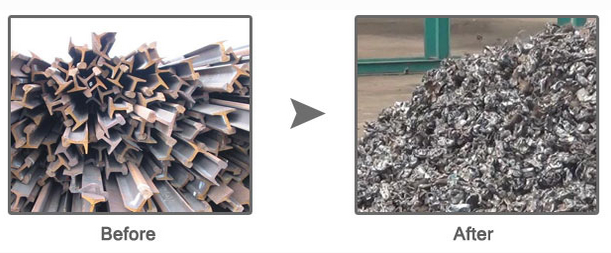

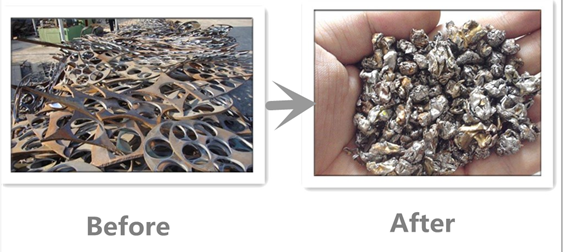

The scrap steel crushing line is designed for the processing of scrap car bodies, tinplate, discarded appliances, bicycles, refrigerators, steel tile, metal cans and other metal scrap. This line has the features of high grinding efficiency, uniform discharging particles with lumpy shapes. It is easy to transport, also enhance the dissolution rate. Scrap steel crusher is driven by geared motor which is power saving 20%. The blades of the scrap steel crusher adopts intermeshing design and made of high-alloy which has good effect on high hardness materials such as unsorted mixed low

quality scrap metal and scrap cars, briquettes, bicycles, motorcycles, etc.Scrap crusher is mainly used in crushing large pieces of scrap, scrap metal, iron metal, metal, scrap metal metal shell and light metal and other materials of large scrap metal crusher environmental protection equipment. Large as a high efficiency, low energy consumption, low noise recovery processing equipment, the large scrap crusher can be based on the material material, characteristics, as well as the output requirements, optional blade structure and feeding.

►2.Configuration structure

Scrap crusher is mainly equipped with: crusher, heavy shredders, conveyor belt, magnetic separator, motor, electric control box, dust removal equipment and other ancillary equipment. Equipment using fully automated production, to achieve the intelligent production, improve production yield and efficiency.

►3.Working Principle

The working principle of the scrap crusher is the process of sorting metal and scrap metal material by shredding the scrap metal material and then the secondary crushing and magnetic separator. The large-scale scrap crusher is cut by the high-speed rotating tool. The smaller diameter of the screen will be a one-time material broken to smaller size particles, usually used as a secondary crushing equipment. Compact design, save space, tilt up and down the box, easy to replace the blade, high safety factor bearings, to reduce the use of improper damage caused by the probability of bearing, roller and chassis as a whole to ensure that between the knife and set knife The shear gap accuracy. Scrap production line with high strength, good toughness, easy to break and wear and other characteristics, in the work to ensure a sharp blade, disassembly, maintenance, maintenance, very convenient.

►4.Applicable materials

►4.Applicable materials

Scrap metal, scrap metal, scrap metal products, irregular metal products, scrap cars, scrap steel, metal, scrap steel, scrap iron, roll gate and other scrap metal recycling processing and sorting.

►5.Application of Scrap Steel Crushing Line

Squashed or not squashed whole car with or without engines;

Cutting or packing pocessed thin materials with density not more than 1t/m3;

Scrap steel plates with thickness less than 6mm, width less than 2.6m, length less than 5m;

Household appliances such as air conditioners, washing machines, refrigerators and so on.

►6.Service purposes

Pre-sale services: to provide customers with project design, process planning, for you to develop an optimized combination of equipment programs, at the same time according to your special needs of the design and manufacture of products for your technical training operations.

Sales service: with you to complete the acceptance of equipment to help develop the construction program and detailed process.

After-sales service: Juno Arrange technical engineers to the site to guide the installation of equipment, commissioning the scene and training operators.

Product quality: except for wearing parts within one year of quality assurance for life maintenance.

►7.Materials that can NOT be processed:

►7.Materials that can NOT be processed:

Steel cable with diameter more than 22mm, length more than 7.5m;

Alloy steel shaft with diameter more than 25mm;

Mild steel shaft with diameter more than 37mm;

Board with thickness over 20mm, length more than 300mm;

Board with thickness over 25mm, length more than 150mm;

Structural Profiles with cross-section more than 12.5mm;

Steel bars with diameter greater than 40mm;

High carbon steel round bar with diameter greater than 12mm;

Ingots, billets and similar materials, etc.

For materials that can not be broken, there is discharge door in the upper part of the crusher to protact protect the machine. Users can quickly open the discharge door, so that the materials that can not be broken are ejected from the crusher.

HR1200 Large recycling bases Mu

HR1200 Large recycling bases Mu Plastic Crusher Plastic Recycli

Plastic Crusher Plastic Recycli Plastic Crusher

Plastic Crusher Scrap Aluminum Crusher

Scrap Aluminum Crusher