http://www.vidacrusher.com

►1. Products:

►1. Products:

Disc-type chipper series is my famous product developed for many years, can be the size of raw materials, including logs, boards, veneer, bamboo, wood, corn stalks, cotton, reed and other non-wood fiber rods into uniform The length of the material, the length of the material can be adjusted within a certain range, it is by the rack, cutter, (knife with two to six knife) feed, power and other components, this series has a reasonable structure Reliable, simple operation, good quality raw materials, high yield, low energy consumption, easy maintenance, high production efficiency, suitable for paper mills, fiberboard mills, particleboard and wood production base and edible fungus production of raw materials processing, is the user's ideal equipment The Direct mouth chip machine is a new development, the inlet from the ramp to straight mouth, with the conveyor belt with the use.

►2. Disc chipper classification:

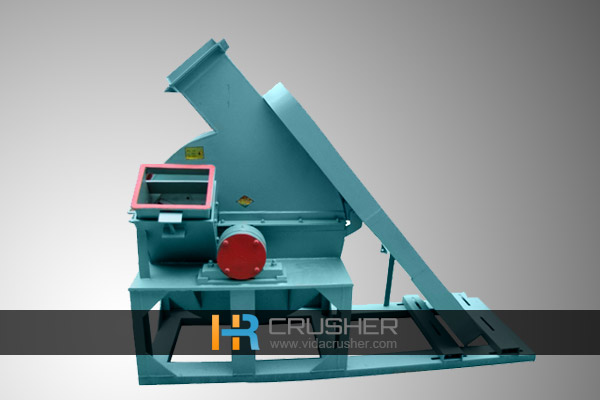

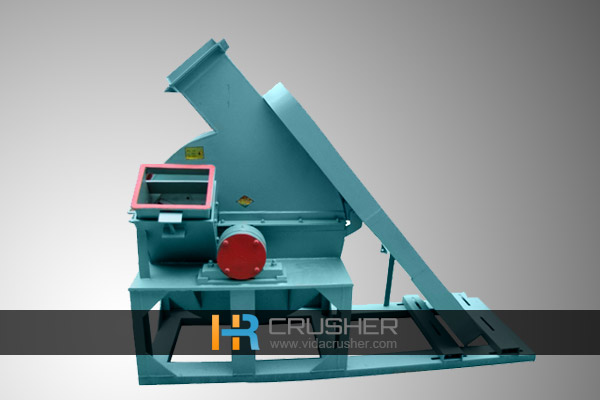

Disc chipper has two kinds of fixed and mobile type. Fixed for the factory; mobile type is generally used for forest areas. According to the structure of the working parts of the sub-drum chipper and disc chipper two, according to the feed method points and ramus feeding and flat mouth feeding two types. Chipper mainly by the host, coupling, chassis, motor and other four parts, including chipper host by the cutter, up and down the shell, feeding mouth and outlet and other components.

The machine can be adjusted according to the need to cut the blade, the production of different specifications and thickness of the wood. In order to meet the different requirements of the length of wood chips in papermaking, fiberboard and particleboard industry, the length of wood chips can be adjusted within a certain range. Disc chipper, compact and reasonable structure, easy operation, large production capacity, wood chips pass rate is high, the unit of wood production of low energy consumption, is the ideal production of high quality wood chips.

►3. Disc chipper Uses:

Disc-type chipper can cut the diameter of 200mm below the logs, trails and branches of wood, for pulp mill, wood field, paper mills, wood chip factory, can be processed, pine, Zamu, Yang wood, fir, Because of its compact structure, small footprint, good quality chipper, low power consumption, and suitable for mobile operation, widely used in small and medium-sized particleboard and fiberboard production enterprises of the preparation section, can also be used for self-employed for the production of wood chips.

►4. disc chipper features:

1) I produced the disc wood chipper is the production of high quality wood chip a special equipment, widely used in papermaking, particleboard, MDF and other industrial production of the preparation section and a single production base of wood, cutting raw materials are mainly logs The

2) the use of low-voltage or high-voltage motor, large disc-type wood chipper pulley drive and direct drive two; feed level and tilt in two ways, the material is also on the material and the next two ways.

3) compact structure, reasonable layout, easy installation, easy operation and maintenance, high production capacity; cutting logs, wood chips of high quality, and the length of the chip can be within the provisions of the free adjustment, is the domestic advanced disc wood chipper.

4) production in the 2 to 160 cubic meters per hour, the user can choose their own models.

5) by the base, cutter, feed, cover, electronic control system and other components.

6) In order to meet the market high quality, high efficiency, high-grade requirements, our company on the disc-type wood chippers series of products year after year to update, and continuously improve product quality. The company series of wood chipper exported to many European countries. At present, our company series disc chipper cutter with wear-resistant pad chrome, Flying knife, the end of the knife, flying knife with special steel made of special. Large disc-type wood chipper tool changer door with push-pull and manual two, available for users to buy. Bringing together the latest technology, the new large-scale disc chippers high yield, low energy consumption, wood chip high quality, cost-effective.

HR1200 Large recycling bases Mu

HR1200 Large recycling bases Mu Plastic Crusher Plastic Recycli

Plastic Crusher Plastic Recycli Plastic Crusher

Plastic Crusher Scrap Aluminum Crusher

Scrap Aluminum Crusher