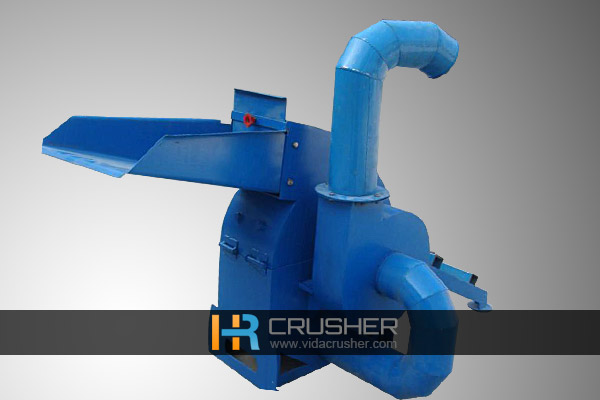

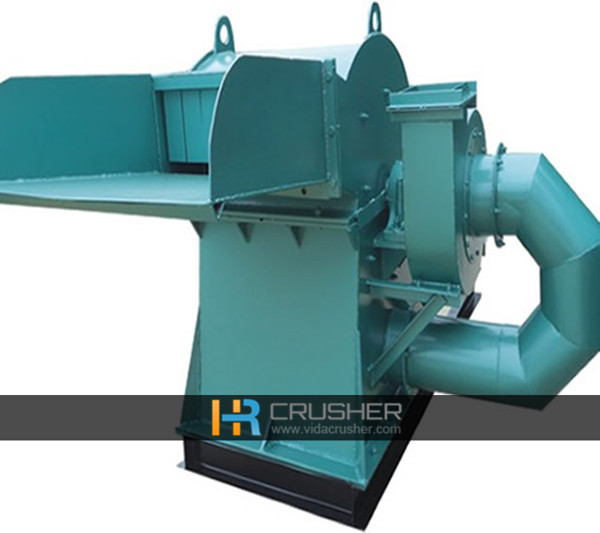

Wood grinder

Mobile/WhatsApp: 008613592505674

http://www.vidacrusher.com

►1.Product Introduction:

Wood grinder is also called hammer crusher. It is suitable for the crushing of mid-hard and light erosive materials, whose pressure resistance strength is no more than 100Mpa and humidity lower than 15%, such as coal, salt, chalk, gypsum, blocks, limestone, etc. The hammer mill can be also used for crushing wood branches, chips, rice, straw, wheat straw, corn straw, grass, river reeds, palm husk, soybeans husk, coffee husk, paddy straw, sunflowers stalk, bamboo and other agro-waste etc.

►2.Working Principle:

Hongrun wood grinder is a kind of crusher shreding the material into fine particles. A hammer mill is essentially a steel drum containing a vertical or horizontal cross-shaped rotor on which pivoting hammers are mounted. The hammers are free to swing on the ends of the cross. The rotor spins at a high speed inside the drum crashing the material fed into the feed hopper. The material is impacted by the hammers on the ends of the rotating cross and thereby shredded and expelled through screens in the drum.

►3. Wood grinder advantages:

The use of Wood grinder can reduce environmental pollution, have a high utilization value, but also crusher in the faster, ideal, affordable a crushed wood equipment. Finished shape from the sawdust, granular to the sheet can be free to adjust the advantages and uses of wood grinder is also a lot.

1) Wood grinder (sawdust mill, wood shredder)Making fine

2) high processing technology, the use of double body, the body into the tap water to play a role in water.

3) into a new material, play a noise, cooling function.

4) noise in the production of small, no vibration. Crushed wood can be used to make wood chips and binder and even press the composite board, used to do decoration ceiling, noise insulation. Sawdust can be used to grow mushroom culture medium, can also be blended in the soil to do potted aquaculture "pots of soil", so that can make the use of wood crusher greatly increased.

►4.Packaging

Ways of Packing:

1. Machine is wrapped by PP-Bubble or plastic fillm;

2. Packed with wooden case and loaded in container.

HR1200 Large recycling bases Mu

HR1200 Large recycling bases Mu Plastic Crusher Plastic Recycli

Plastic Crusher Plastic Recycli Plastic Crusher

Plastic Crusher Scrap Aluminum Crusher

Scrap Aluminum Crusher